Fabrication and construction are integral components of countless industries, ranging from infrastructure development to manufacturing and beyond. Whether you’re a seasoned professional or just starting, having a comprehensive understanding of fabrication and construction processes is essential. This handbook aims to provide a thorough overview, covering key concepts, techniques, and best practices to empower individuals and organisations in these fields.

Understanding Fabrication and Construction:

Fabrication:

Fabrication involves the creation of structures, machines, or components through cutting, shaping, and assembling raw materials. It encompasses various processes such as welding, machining, casting, and forging. Fabricated products range from simple consumer goods to complex industrial machinery.

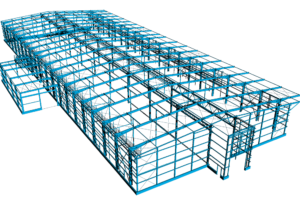

Construction:

Construction is the process of assembling infrastructure or buildings according to architectural and engineering designs. It involves activities like site preparation, foundation laying, erection of structural components, and finishing touches. Construction projects vary widely in scale and complexity, from residential homes to skyscrapers and infrastructure projects like bridges and highways.

Key Concepts and Techniques:

Materials Selection:

Choosing the right materials is crucial for both fabrication and construction projects. Factors such as strength, durability, cost, and environmental impact must be considered. Common materials include steel, concrete, wood, and composites.

Blueprint Reading:

Understanding technical drawings and blueprints is essential for interpreting design specifications and executing fabrication and construction tasks accurately.

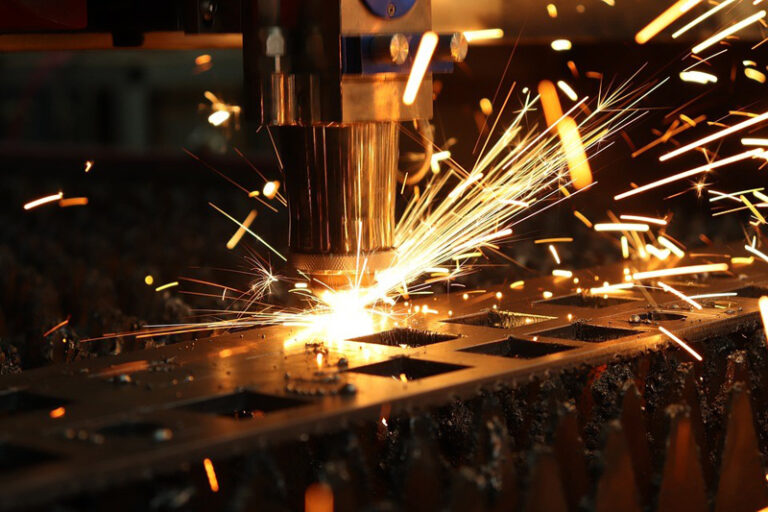

Welding:

Welding is a fundamental process in fabrication, joining metal parts by melting them together. Different welding techniques, such as arc welding, MIG welding, and TIG welding, are employed based on the material and application.

Machining:

Machining involves the removal of material from a workpiece to achieve desired shapes and dimensions. Techniques include milling, turning, drilling, and grinding, performed using various machine tools.

Structural Analysis:

Engineers use structural analysis techniques to assess the integrity and stability of fabricated and constructed structures under different loads and conditions.

Project Management:

Effective project management ensures that fabrication and construction projects are completed on time, within budget, and according to specifications. It involves planning, scheduling, resource allocation, and risk management.

Best Practices:

Safety First:

Safety should always be the top priority in fabrication and construction. Workers must follow proper safety protocols, use personal protective equipment (PPE), and undergo training to prevent accidents and injuries.

Quality Assurance:

Implementing quality control measures throughout the fabrication and construction process ensures that the final products meet performance standards and regulatory requirements.

Collaboration and Communication:

Effective communication and collaboration among team members, including engineers, fabricators, contractors, and clients, are essential for project success.

Continuous Learning:

Fabrication and construction technologies evolve rapidly. Staying updated with the latest advancements, techniques, and regulations is critical for professional growth and competitiveness.

Sustainability:

Embracing sustainable practices, such as using recycled materials, reducing waste, and optimising energy efficiency, helps minimise the environmental impact of fabrication and construction activities.

Conclusion:

Fabrication and construction are dynamic and multifaceted fields that require a combination of technical expertise, creativity, and collaboration. Whether you’re involved in building infrastructure, manufacturing machinery, or creating consumer products, this handbook serves as a valuable resource for understanding the fundamentals and best practices of fabrication and construction. By embracing knowledge and innovation, individuals and organisations can embark on projects with confidence, knowing they have the tools to succeed in this ever-evolving industry.