Steel fabrication is a demanding craft that requires precision, skill, and the right tools to achieve quality results. Whether you’re a seasoned professional or just starting out in the field, having the right equipment can make all the difference in your productivity and the quality of your work. In this article, we’ll explore some essential tools that every steel fabrication pro should have in their arsenal.

Angle Grinder:

An angle grinder is a versatile tool that is indispensable in steel fabrication. It can be used for cutting, grinding, and polishing metal with ease. Look for a high-powered grinder with a variety of attachments to tackle different tasks efficiently.

Welding Machine:

Welding is a fundamental process in steel fabrication, and having a reliable welding machine is essential. Invest in a machine that offers the right combination of power, versatility, and ease of use for your specific needs. Whether it’s MIG, TIG, or stick welding, choose a machine that meets the demands of your projects.

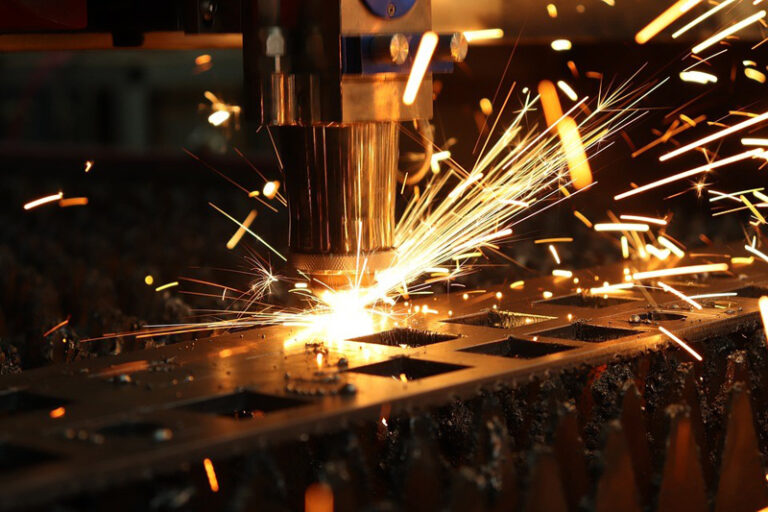

Cutting Torch:

For precise cutting of thick steel materials, a cutting torch is a must-have tool. Whether you’re making straight cuts or intricate shapes, a cutting torch provides the flexibility and control needed to achieve clean and accurate results.

Magnetic Base Drill:

Drilling accurate holes in steel can be challenging without the right equipment. A magnetic base drill offers stability and precision, allowing you to drill holes quickly and accurately even in awkward positions or on vertical surfaces.

Measuring Tools:

Accurate measurements are crucial in steel fabrication to ensure precise fits and alignments. Invest in high-quality measuring tools such as tape measures, squares, levels, and calipers to achieve accuracy in your work.

Safety Gear:

Safety should always be a top priority in steel fabrication. Make sure to invest in proper safety gear including welding helmets, gloves, safety glasses, and protective clothing to protect yourself from sparks, heat, and flying debris.

Clamps and Vises:

Clamps and vises are essential for holding pieces securely in place during fabrication and welding. Choose a variety of sizes and types to accommodate different shapes and sizes of workpieces, ensuring stability and accuracy throughout the fabrication process.

Conclusion:

Having the right tools is essential for success in steel fabrication. By investing in high-quality equipment and maintaining proper safety practices, you can enhance your productivity, efficiency, and the quality of your work. Whether you’re cutting, welding, drilling, or measuring, having the right tools at your disposal will enable you to tackle any fabrication project with confidence and precision.